An Effective Pdca Process Requires Which of the Following

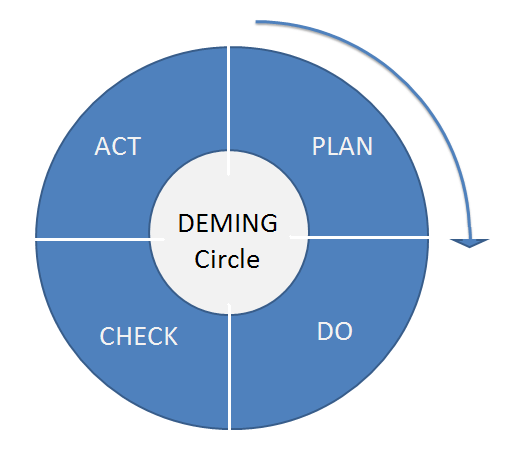

Train and instruct to ensure everyone is competent to carry out their work. The methodology is a four-step cycle formerly named the Deming cycle.

Illustration Of Isms Pdca Process Download Scientific Diagram

The PDCA cycle also requires that those who will be involved buy into and believe in the process.

. It is also known as the Deming circlecyclewheel the Shewhart cycle the control circlecycle or plandostudyact. Japanese term meaning continuous improvement. The inbuilt plan test and feedback mechanism of PDCA allow fixing and improving at the implementation stage of the process.

Plan Do Check and Act. Therefore it is also known as the Deming cycle or Deming Wheel. Supervise to make sure that arrangements are followed.

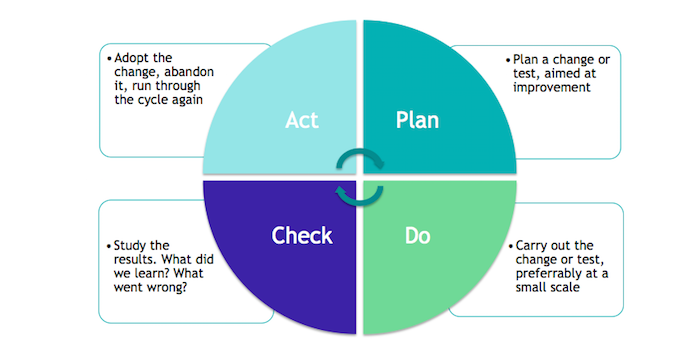

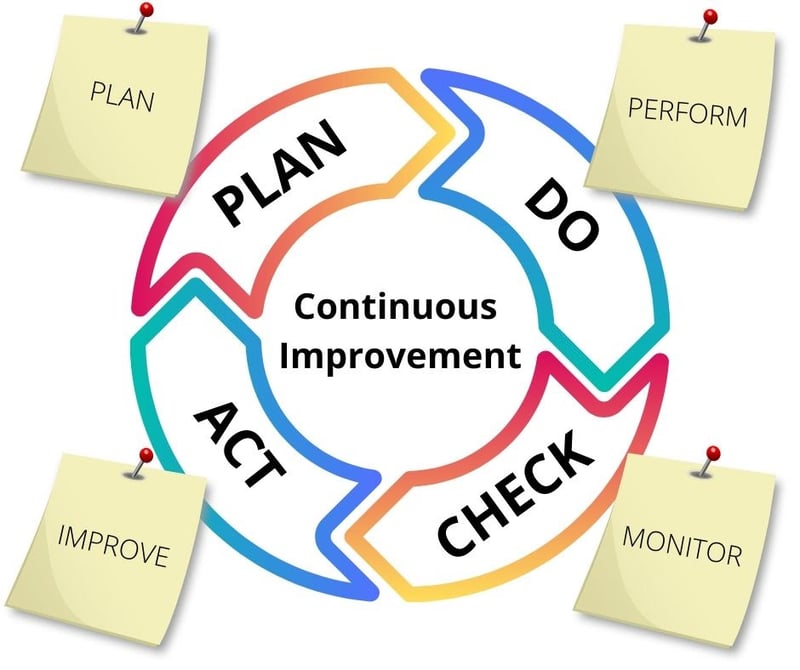

PDCA cycle is an iterative process for continually improving products people and services. This concept is a cycle for implementing change which when followed and repeated would lead to repeated improvements in the process it was applied to. Because its a cyclical tool it also promotes continuous process improvement.

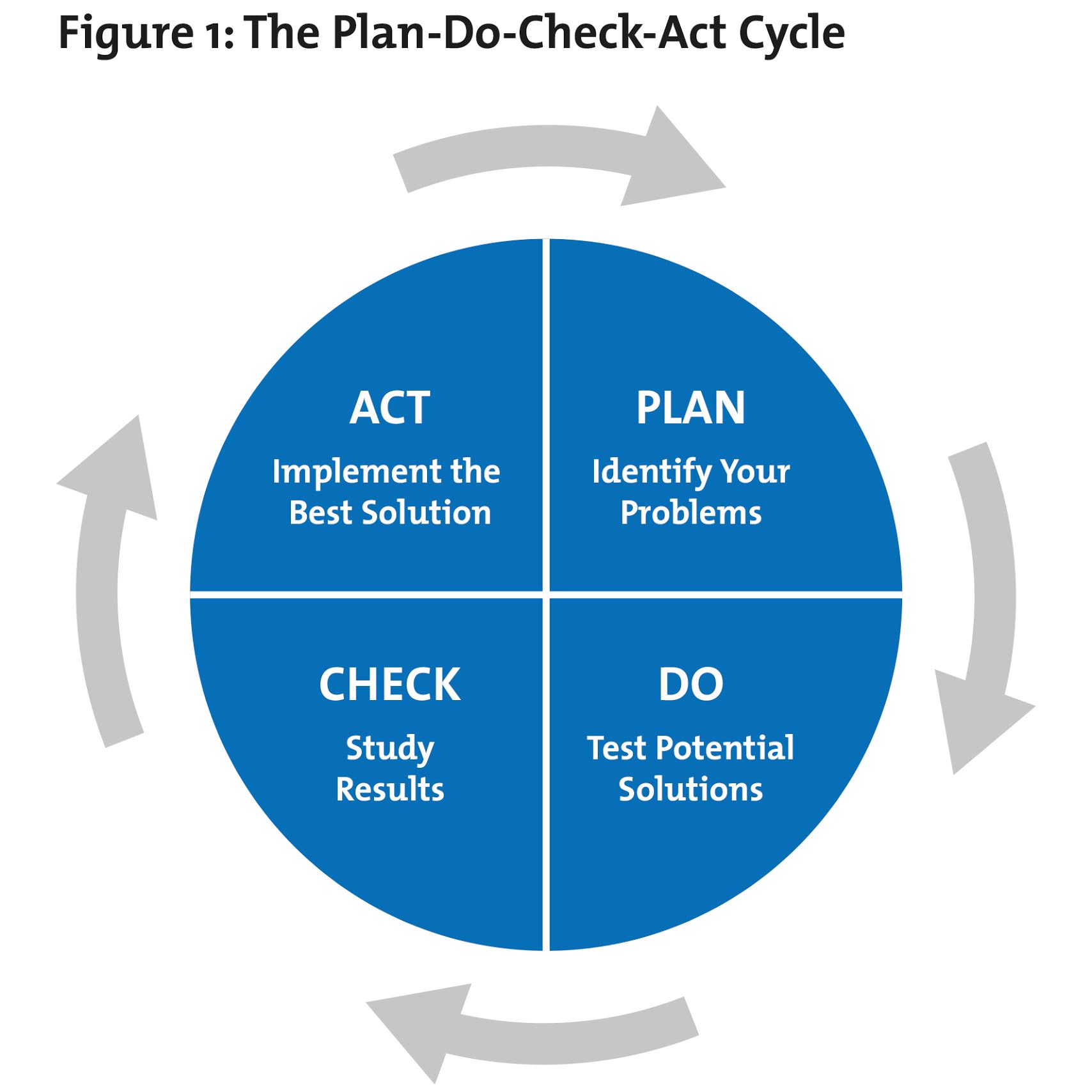

Phases of the PDCA Model The phases of the PDSA model below assume that just one underlying or root cause will be addressed by testing just one intervention. The PDCA model was developed in the 1950s by William Deming as a learning or improvement process based on the scientific method of problem-solving. PDCA increases workers self control by.

Its focus is to solve problems by following the four phases indicated by its letters. There are four stages to the PDCA cycle. It is best to use the PDCA cycle when as defined by ASQ.

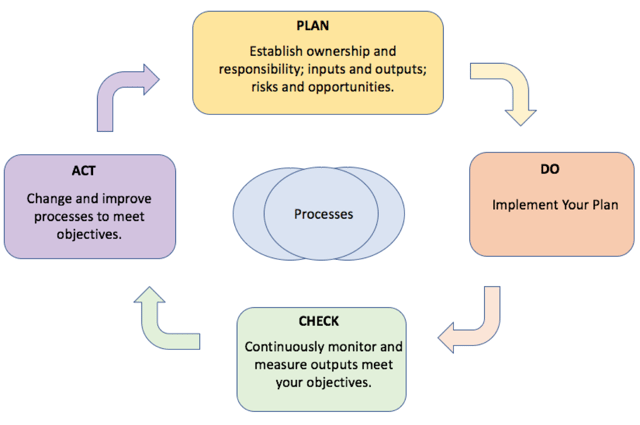

The Plan-Do-Check-Act PDCA cycle also known as the Deming wheel or the Deming cycle is an iterative method for continual improvement of processes products or services and is a key element of lean management. Look at the root causes of any issues and set goals to overcome these obstacles. The most important of these processes is the PDCA cycle which guides the service owner through effective continual service improvement.

Following the PDCA approach companies. Plan-Do-Check-Act or PDCA for short is a system for continuous improvement which ensures that every production cycle for a companys product results in measurable positive changes in the final output and that the company is capable of adjusting. Day to day kaizen.

It provides continuous improvement. Giving workers the means of evaluating plans before implementation and the controlling them. The PDCA cycle can seem to move a little slow as its designed to have everyone involved really think over the issues and develop appropriate solutions that prove to work.

What Does an Effective PDCA Process Require. PDCA cycle is the abbreviation of plan-do-check-act. William Edwards Deming introduced the PDCA method.

PDCA cycle is the abbreviation of plan-do-check-act. The plan-do-check-act cycle breaks the project into small manageable steps and allows gradual incremental improvements. When undertaking the PDCA process the.

It is a project planning tool and is a key element of lean management. It is widely implemented as a part of a tool within larger improvement methodologies or as a stand-alone approach to quality control and change management. The PDCA methodology aims to improve processes occurring in a company and help eliminate recurring mistakes.

Rather than representing a one-and-done process the Plan-Do-Check-Act cycle is an ongoing feedback loop for iterations and process improvements. Just as a circle has no end the PDCA cycle should be repeated again and again for continuous improvement. Deming PDCA Cycle.

The PDCA methodology aims to improve processes occurring in a company and. The PDCA cycle is considered a project planning tool. The added O stands for observation or as some.

The 4 stages of the. Plan-Do-Check-Act also called PDCA is a cycle that was originated by Walter Shewhart and made popular by Edward Deming two of the fathers of modern quality control. The Plan-Do-Check-Act cycle is a popular business management method to achieve continuous improvement in an organization.

The Effectiveness of the Plan-Do-Check-Act PDCA Cycle. How to Use PDCA to Improve Personal Performance. PDCA Cycle is applicable at 3 levels.

In the 1950s a famous management scholar Dr. Explaining the PDCA Cycle in Detail. The PDCA Cycle This cycle is a management approach developed by Edwards Deming and results in improved quality increased productivity and results in a more competitive position.

PDCA is an iterative design and management method used in business for the control and continuous improvement of processes and products. The Plan-do-check-act cycle Figure 1 is a four-step model for carrying out change. 3 Tools for Quality Management and Processes.

When to use the PDCA cycle. By Shmula Contributor Last Updated November 12 2017. The methodology is a four-step cycle formerly named the Deming cycle.

PDCA cycle helps in managing change effectively. By following the PDCA cycle teams develop hypotheses test those ideas and improve upon them in a continuous improvement cycle. It became an integral part of what is known today as Lean management.

Cogent picture of key points in the PDCA cycle and can be an effective venue to tell the story as the team moves through its improvement work. The PDCA cycle is a method for continuous improvement. Provide the right tools and equipment to do the job and keep them maintained.

Other terms of the PDCA cycle include the Deming circle the Shewhart cycle the control circle or the Plan-Do-Study-Act PDSA cycle. Another version of this PDCA cycle is OPDCA. Examples of a PDCA cycle.

While PDCAPDSA is an effective business tool you can also use it to improve your own performance. Decide on the preventive and protective measures needed and put them in place. The PDCA cycle is a useful.

The change process under PDCA entails incorporating the parameters that require change in the planning component plan implementation of a prototype do the review of the prototype for suitability and performance check or learn and widespread implementation or successful implementation of the prototype act. Identify whats holding you back personally and how you want to progress. The Plan-Do-Check-Act model includes solutions testing analyzing results and improving the process.

Deming PDCA cycle refers to a repeated four-step management model that ensures the continuous improvement of products and services in the industry. The approach is iterative - that is it is a cycle. PDCA is an acronym that gives name to a tool used in process quality management.

Pdca Is Toyota S Best Problem Solving Technique It S A Four Step Approach That Allows Agile Project Management Business Process Management Business Leadership

The Pdca Method Or Deming Wheel For Your Improvement Work Life Management

Pdca Process Pdca Wikipedia Process Improvement Business Process Change Management

Process Approach And Pdca In Iso 9001 2015

Powerpoint Pdca Cycle Sketchbubble Personal Development Plan Template Personal Development Plan How To Plan

Continuous Improvement Poster The Pdca Cycle Light Process Improvement Change Management Business Leadership

The Pdca Cycle In Energy And Utilities Management Viridis

How To Implement The Pdca Cycle Plan Do Check Act Free Template

Ict Institute Information Security And Pdca Plan Do Check Act

Pdca Plan Do Check Act From Mindtools Com

How To Use Pdca Cycle To Improve Process Efficiency Tallyfy

The Pdca Cycle Under Ims Environmental Management System Safety Management System Business Model Example

Change Management Document Management System Business Management

Plan Do Check Act Pdca Infographic How To Plan Business Planning Business Leadership

What Is Pdca And Why It Matters For Marketers

Follow The Pdca Cycle In Order To Gain Success Critical Thinking Skills Work Quotes Health And Safety Poster

What Is Kaizen Continuous Improvement Definition From Whatis Com Kaizen Process Improvement Kaizen Process

What Does An Effective Pdca Process Require

Pdca Cycle Management Infographic Business Management Degree Safety Management System

Comments

Post a Comment